What Is a Stepper Motor & How Does It Work?

A Practical Guide Engineers Actually Use

Introduction: Why Stepper Motors Still Matter in Automation

If you work with CNC machines, 3D printers, medical devices, or industrial automation systems, chances are you have already used a stepper motor—whether you realized it or not.

So, what is a stepper motor, and how does a stepper motor work in real-world applications? Beyond textbook definitions, stepper motors remain widely used because they provide predictable motion, simple control, and excellent low-speed torque without the complexity of closed-loop feedback systems.

At HDBMOTOR, stepper motors are still among the most requested motion components from OEM customers, especially in applications where reliability, repeatability, and cost control are more important than extreme speed.

What Is a Stepper Motor?

A stepper motor is a type of electric motor that rotates in discrete angular steps instead of continuous motion. Each electrical pulse sent to the motor corresponds to a precise mechanical movement.

Position control without an encoder

Speed defined by pulse frequency

Direction controlled digitally

Holding torque available at standstill

How Does a Stepper Motor Work?

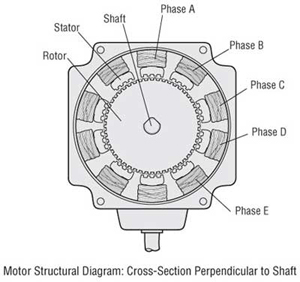

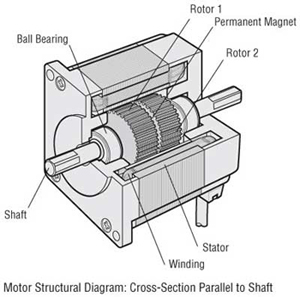

To understand how a stepper motor works, it is helpful to focus on magnetic alignment rather than rotational speed.

The stator contains multiple electromagnetic windings

The rotor is either a permanent magnet or a toothed iron structure

When current flows through a stator phase, a magnetic field is generated

The rotor moves to align with that magnetic field

Sequentially switching phases produces controlled rotation

Most industrial stepper motors operate with a step angle of 1.8° (200 steps per revolution) or 0.9° (400 steps per revolution).

Types of Stepper Motors

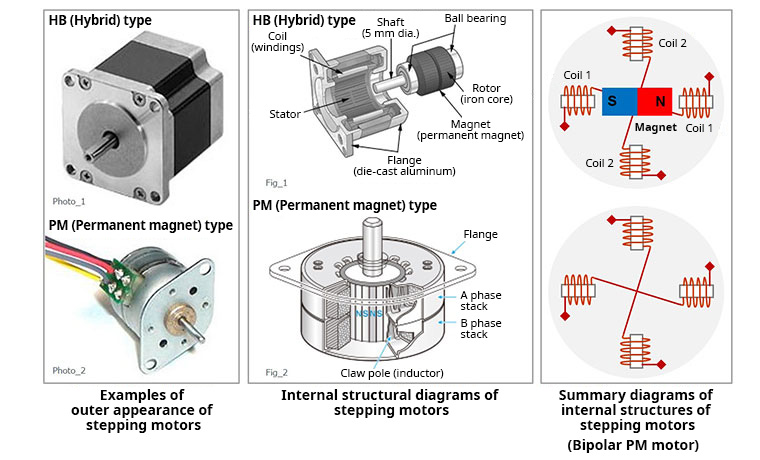

Permanent Magnet (PM) Stepper Motors

PM stepper motors use permanent magnets in the rotor. They feature a simple structure and low cost but offer limited torque and positioning accuracy.

Variable Reluctance (VR) Stepper Motors

VR stepper motors do not use permanent magnets. The rotor aligns based on magnetic reluctance, providing fast response but low holding torque.

Hybrid Stepper Motors

Hybrid stepper motors combine PM and VR designs, offering higher torque, better resolution, and improved performance.

| Parameter | Hybrid Stepper Motor | Variable Reluctance (VR) | Permanent Magnet (PM) |

|---|---|---|---|

| Rotor Structure | Toothed rotor with permanent magnet | Soft iron toothed rotor | Permanent magnet rotor |

| Permanent Magnet | Yes | No | Yes |

| Operating Principle | Magnetic attraction & reluctance torque | Minimum magnetic reluctance | Magnetic attraction of permanent magnet |

| Typical Step Angle | 1.8° / 0.9° | 1.2° / 1.5° | 7.5° / 15° |

| Positioning Accuracy | High | Medium | Low |

| Output Torque | High | Low | Medium |

| Holding Torque (Power Off) | Strong | Nearly none | Available |

| Dynamic Performance | Excellent | Good | Fair |

| Speed Capability | Medium–High | High | Low–Medium |

| Mechanical Complexity | High | Low | Low |

| Cost Level | Medium–High | Low | Low–Medium |

| Control Difficulty | Medium | Medium | Low |

| Typical Sizes | NEMA 8 / 11 / 17 / 23 / 34 | Non-standard | 20mm / 25mm / 28mm |

| Typical Applications | CNC machines, 3D printers, industrial automation, robotics | Educational equipment, lab systems | Home appliances, instruments, valves |

| Market Adoption | ★★★★★ (Mainstream) | ★ | ★★ |

Why Stepper Motors Are Used in Automation

No feedback wiring required

Excellent low-speed torque

High positioning repeatability

Lower system cost

Easy integration with PLCs and motion controllers

Open-Loop vs Closed-Loop Stepper Systems

A common misconception is that stepper motors are inaccurate without feedback. Properly sized open-loop systems work reliably.

For variable loads or higher reliability, closed-loop steppers with encoders eliminate step loss while keeping stepper advantages.

Closed-Loop Stepper Motor Position Error Exceeded: Causes, Diagnosis & Solutions

Torque, Speed, and Holding Characteristics

Torque decreases as speed increases

Holding torque exists at zero speed

Resonance may occur at mid-speed ranges

Microstepping improves smoothness but not torque

Typical Stepper Motor Applications

CNC machines

3D printers

Packaging equipment

Medical pumps and analyzers

Textile and labeling machines

Industrial linear actuators

| Application | Key Requirements | Why Stepper Motor? | Typical Use Cases |

|---|---|---|---|

| CNC Machines | High precision, repeatability | Accurate position without feedback | X/Y/Z axes, tool changers |

| Medical Devices | Smooth, low vibration, high reliability | Predictable movement, microstep control | Pumps, diagnostic equipment, lab automation |

| Automation Equipment | Repetitive positioning, cost-effective | Easy integration, reliable performance | Conveyors, labeling, assembly robots |

Choosing the Right Stepper Motor

Required torque with safety margin

Operating speed range

Duty cycle and thermal limits

Load inertia and mechanical transmission

Driver compatibility

HDBMOTOR Stepper Motor Solutions

NEMA 8 to NEMA 34 stepper motors

High-torque and low-inertia designs

Integrated motor and driver solutions

Custom shaft, winding, and mounting options

Conclusion

Understanding what a stepper motor is and how a stepper motor works enables engineers to design reliable, precise, and cost-effective motion systems. Contact HDBMOTOR to discuss your application or request a technical recommendation.

Recommended Articles:

How to Control Stepper Motor Speed

Stepper Motor Continuous Jitter When Returning to Origin

Top 8 Features of Hybrid Stepper Motors You Should Know