What is a Permanent Magnet Stepper Motor?

A permanent magnet stepper motor (PM stepper motor) works by using the magnetic field created by coil currents to attract or repel the rotor’s permanent magnets. This interaction enables the motor shaft to rotate in discrete steps, allowing for accurate positioning both forward and backward.

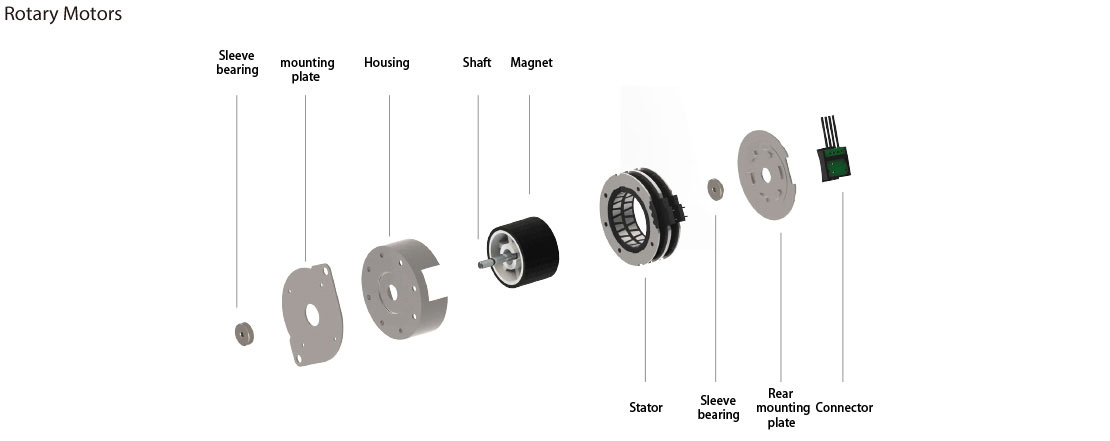

Permanent Magnet Stepper Motor Structure

The motor consists of a rotor equipped with permanent magnets and a stator with multiple coil windings. When electrical pulses energize the coils, the rotor aligns with the magnetic field, moving incrementally with each pulse. This structure supports high repeatability and torque at low speeds.

Operating Principles of Permanent Magnet Stepper Motors

Stepper motor drivers receive external control pulses and direction signals and energize the motor windings accordingly. For each pulse, the rotor moves one step forward or backward, or holds its current position. For example, a 7.5-degree two-phase PM stepper motor completes 48 steps per full revolution. Energizing both phases with DC current holds the rotor steady, with holding torque defining the maximum load it can sustain without moving.

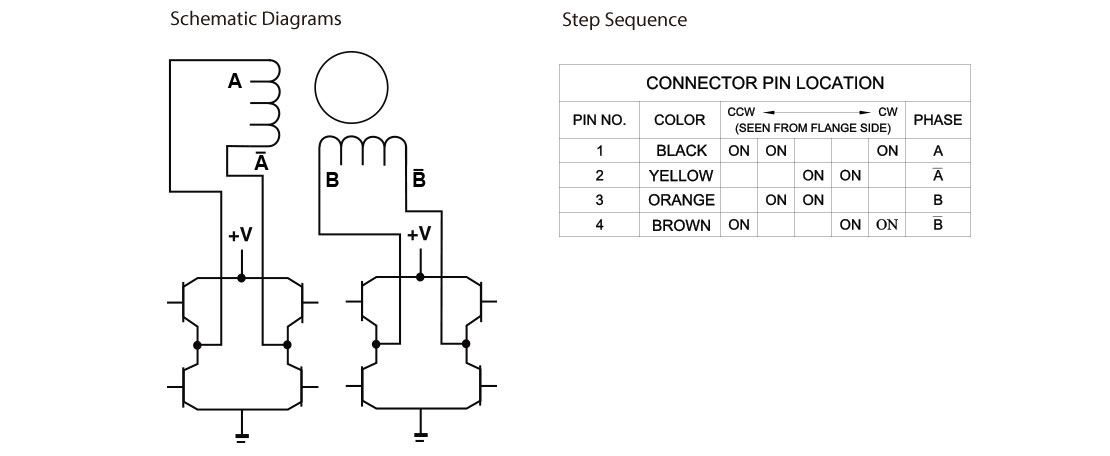

Bipolar vs Unipolar Windings in PM Stepper Motors

Two-phase PM stepper motors come in bipolar and unipolar winding configurations:

Bipolar Motors: Each phase has a single winding; current direction reverses to change rotor position. This requires eight electronic switches to drive but delivers approximately 40% more holding torque due to full winding utilization.

Unipolar Motors: Each phase has two windings connected oppositely. Current alternates between windings within the same phase, requiring only four switches. While simpler, unipolar motors provide less torque compared to bipolar types.

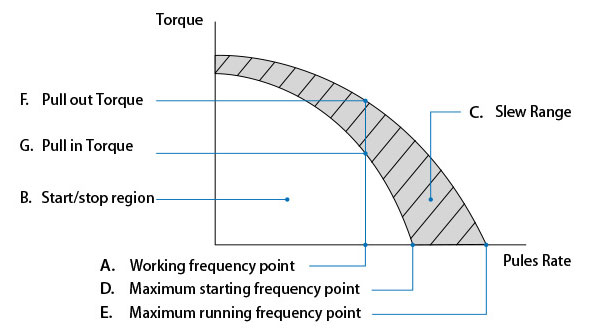

Key Performance Terms and Characteristics

Understanding these terms helps in assessing motor suitability:

A. Working Frequency Point: Relationship between rotation speed (rev/sec) and pulse frequency, calculated by n = q * Hz / (360 * D).

B. Start/Stop Region: The frequency range where the motor can safely start or stop without losing steps.

C. Slew Range: Speed range requiring gradual acceleration/deceleration to avoid step loss.

D. Maximum Starting Frequency Point: Highest speed the motor can start at under no load.

E. Maximum Running Frequency Point: Maximum continuous speed under no load.

F. Pull-in Torque: Maximum torque the motor can achieve when starting directly at a given frequency.

G. Pull-out Torque: Maximum torque while the motor is running, typically higher than pull-in torque due to inertia.

Why Choose a Permanent Magnet Stepper Motor?

Permanent magnet stepper motors provide reliable, repeatable motion control with straightforward pulse-based operation. Their simple structure and effective torque characteristics make them ideal for applications such as CNC machines, robotics, and precise positioning systems.

Recommended Articles:

Stepper Motor Step Angle and Calculation Formula: Complete Guide (2025)

Difference Between Sinking Current and Sourcing Current: 7 Powerful Facts

Motor Torque Calculation Formula: Simple Guide with 5 Key Torque Formulas