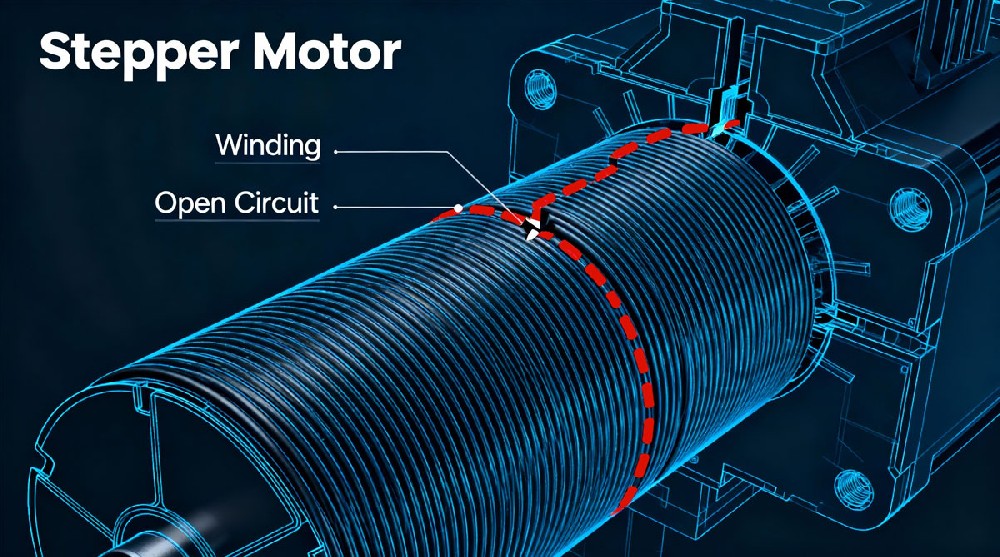

Stepper Motor Winding Open Circuit Failures

The stepper motor alarm "winding open circuit" indicates that the driver detects one or more motor windings have failed to complete an electrical circuit, preventing current flow. This failure can disrupt motor operation and lead to machine downtime. Understanding the causes and troubleshooting steps for stepper motor winding open circuit faults is essential for quick diagnosis and repair.

1. Direct Causes of Stepper Motor Winding Open Circuit Failures

Physical Open Circuit of Motor Winding

This occurs when the winding coil internally breaks or burns out, often due to motor overload leading to overheating. Mechanical impacts or vibrations can also cause winding lead breakage. Continuous high current accelerates insulation aging, potentially resulting in short circuits or coil fusing.

Verification: After powering off, measure the resistance of each phase winding using a multimeter. Normal resistances usually range from a few ohms to several dozen ohms. Infinite resistance indicates an open circuit. Visual inspection after disassembly can reveal damage such as burnt or broken windings.

Wiring Problems

Poor contact in motor leads or connectors is a common cause. Broken wires, especially at bending points, loose or oxidized connections, and incorrect wiring between the driver and motor phases can cause open circuit alarms.

Verification: Gently shake the motor cable to see if the alarm disappears intermittently. Use a multimeter to test continuity and confirm correct phase wiring matching the driver labels.

Driver Failures

Internal damage to driver components like HDBMOTORS or driver ICs caused by output short circuits, excessive current, or poor heat dissipation can lead to winding open circuit alarms.

Verification: Perform a driver replacement test with a known good unit. Use an oscilloscope to check driver output waveforms for missing or abnormal phases.

2. Indirect Causes of Winding Open Circuit Faults

Incorrect Driver Current Settings

Setting driver output current significantly lower than the motor’s rated current may cause false open circuit detections.

Solution: Adjust driver current settings to match the motor’s nameplate specifications via DIP switches or software.

Environmental Interference and Grounding Issues

Strong electromagnetic interference or poor grounding can cause driver misdetections.

Verification: Ensure motor cable routing avoids parallel runs with power cables; use shielded cables with proper single-point grounding and secure drive grounding terminals.

Motor Over-Temperature Protection False Trigger

Incorrect temperature sensor readings can cause the driver to disconnect windings forcibly.

Solution: Inspect or replace temperature sensors or thermistors and verify built-in thermal protection components if present.

3. Emergency Repair and Troubleshooting Steps

Verify Motor Windings: Disconnect motor, measure each phase resistance; repair or replace if abnormal.

Check Wiring and Connectors: Re-crimp terminals, replace poor connectors, and upgrade cables to high-temperature resistant types.

Diagnose Driver: Test driver with a known good motor; inspect internal fuses or power transistors professionally.

4. Preventive Measures

Install electrical protection like fuses and use drivers with overcurrent protection.

Avoid radial shaft forces and ensure flexible couplings; lubricate mechanical parts regularly.

Optimize environment by adding cooling fans, selecting heat-resistant motors, and securing cables against vibration.

5. Repair Cost Reference

Replace motor if winding coil is broken.

Repair or replace driver if power components fail.

Replace cables or connectors if wiring contacts are poor.

Summary:

The core of the stepper motor winding open circuit alarm is an abnormal current loop caused by physical wiring issues, motor winding damage, or driver faults. Step-by-step checks from wiring to driver are vital. When self-diagnosis is challenging, consult manufacturers or professional technicians to prevent further damage.

Recommended Articles:

How to Control Stepper Motor Speed

Stepper Motor Continuous Jitter When Returning to Origin

Top 8 Features of Hybrid Stepper Motors You Should Know