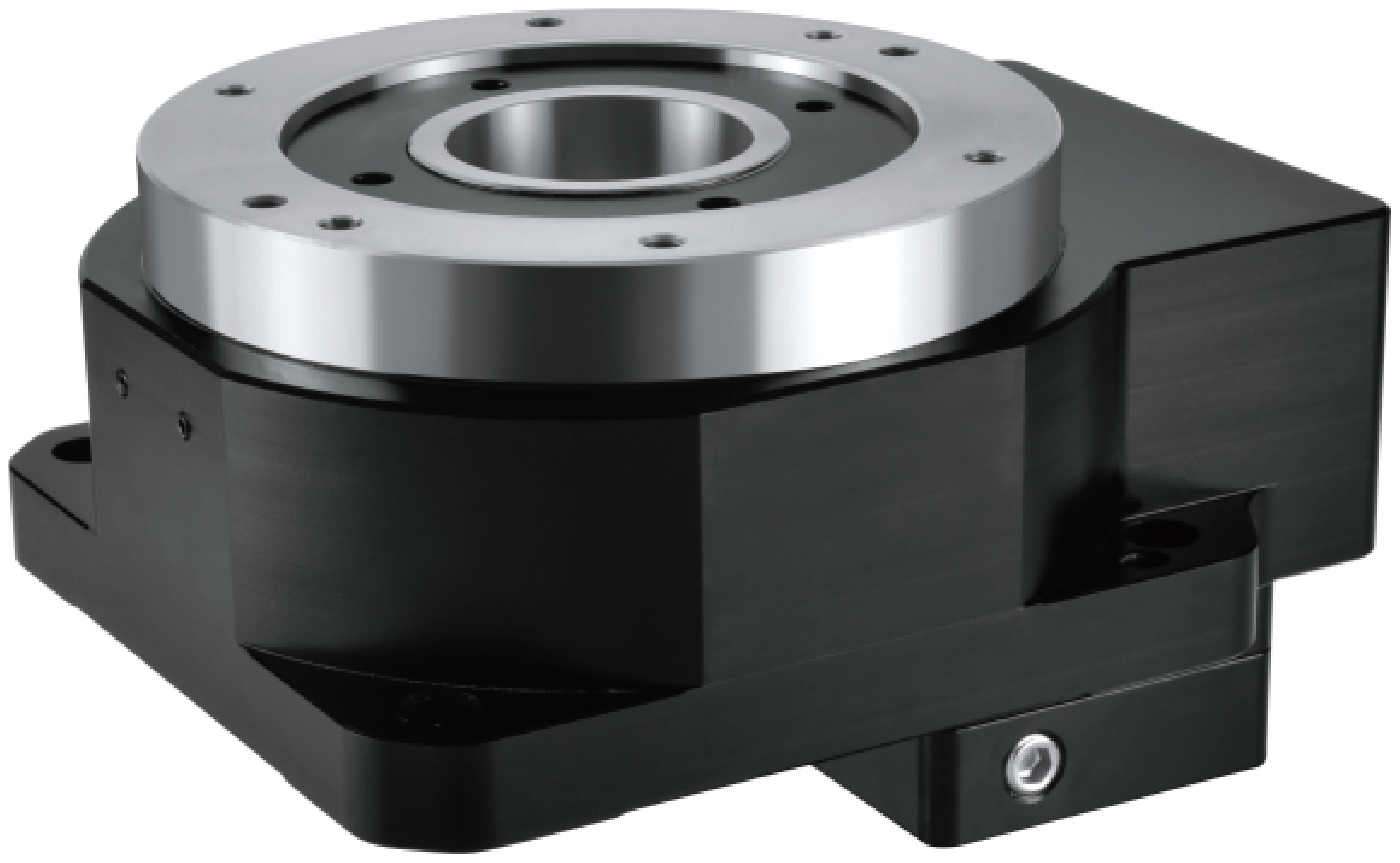

Stepper Motor vs Servo Motor: Which Is Right for Your Project?

In industrial automation and precision motion control, choosing the right motor directly impacts system performance, cost, and reliability. Stepper motors and servo motors are two of the most widely used solutions, each suited for different application requirements. At HDBMOTOR, we help customers select the most appropriate motor based on real engineering needs. This guide compares stepper motors and servo motors to help you make an informed decision.

Stepper Motors: Cost-Effective Open-Loop Control Specialists

A stepper motor converts electrical pulse signals into discrete mechanical movements. Most stepper motors operate in an open-loop control system, meaning no encoder feedback is required. Each pulse corresponds to a fixed step angle, enabling accurate positioning in many applications.

Key Characteristics of Stepper Motors

Precise positioning: Typical step angles of 1.8° or 0.9°. With microstepping, resolution can reach 0.007°.

Simple control: Pulse and direction signals make integration easy with PLCs and controllers.

High holding torque: Excellent low-speed torque for position holding.

Cost-effective: 20–40% lower system cost compared to servo systems.

HDBMOTOR Stepper Motor Solutions

HDBMOTOR provides a wide range of stepper motors for industrial automation, including:

Servo Motors: High-Performance Closed-Loop Control

Servo motors operate in a closed-loop system, using encoder feedback to continuously correct position, speed, and torque. This enables high dynamic response and consistent torque across a wide speed range.

Key Characteristics of Servo Motors

High accuracy: Encoder resolutions from 16-bit to 23-bit.

High speed: Stable operation at 3000–6000 RPM.

Overload capability: 200–300% peak torque for short durations.

Smooth motion: Low vibration and low noise.

HDBMOTOR Servo & Closed-Loop Solutions

Two-Phase Closed-Loop Stepper Motors

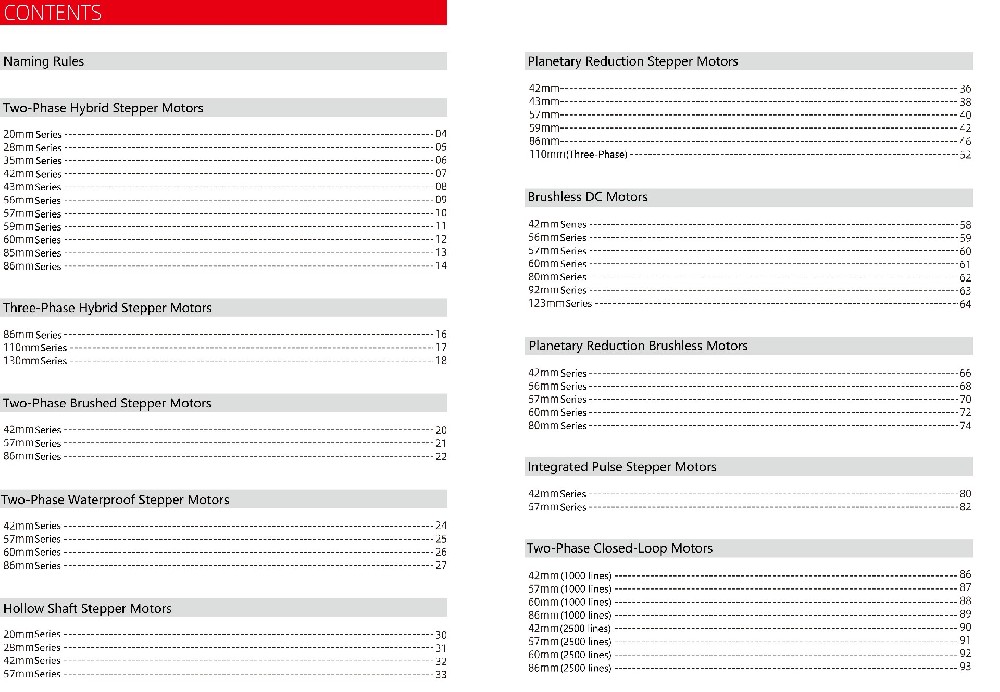

Planetary Reduction Brushless Motors

Brushless DC Motors (BLDC)

Advanced Motor Drivers

Stepper Motor vs Servo Motor: Comparison

| Feature | Stepper Motor | Servo Motor |

|---|---|---|

| Control System | Open-loop | Closed-loop (encoder feedback) |

| Position Accuracy | High (with microstepping) | Very high (16–23 bit) |

| Speed Range | Up to 2000 RPM | Up to 6000 RPM |

| Torque at Low Speed | High holding torque | Stable torque |

| System Cost | Lower | Higher |

How to Choose the Right Motor for Your Project

Choose a stepper motor if your application is cost-sensitive, requires moderate speed, and stable positioning.

Choose a servo motor if you need high speed, fast acceleration, high precision, and dynamic load control.

HDBMOTOR: Your Reliable Motion Control Partner

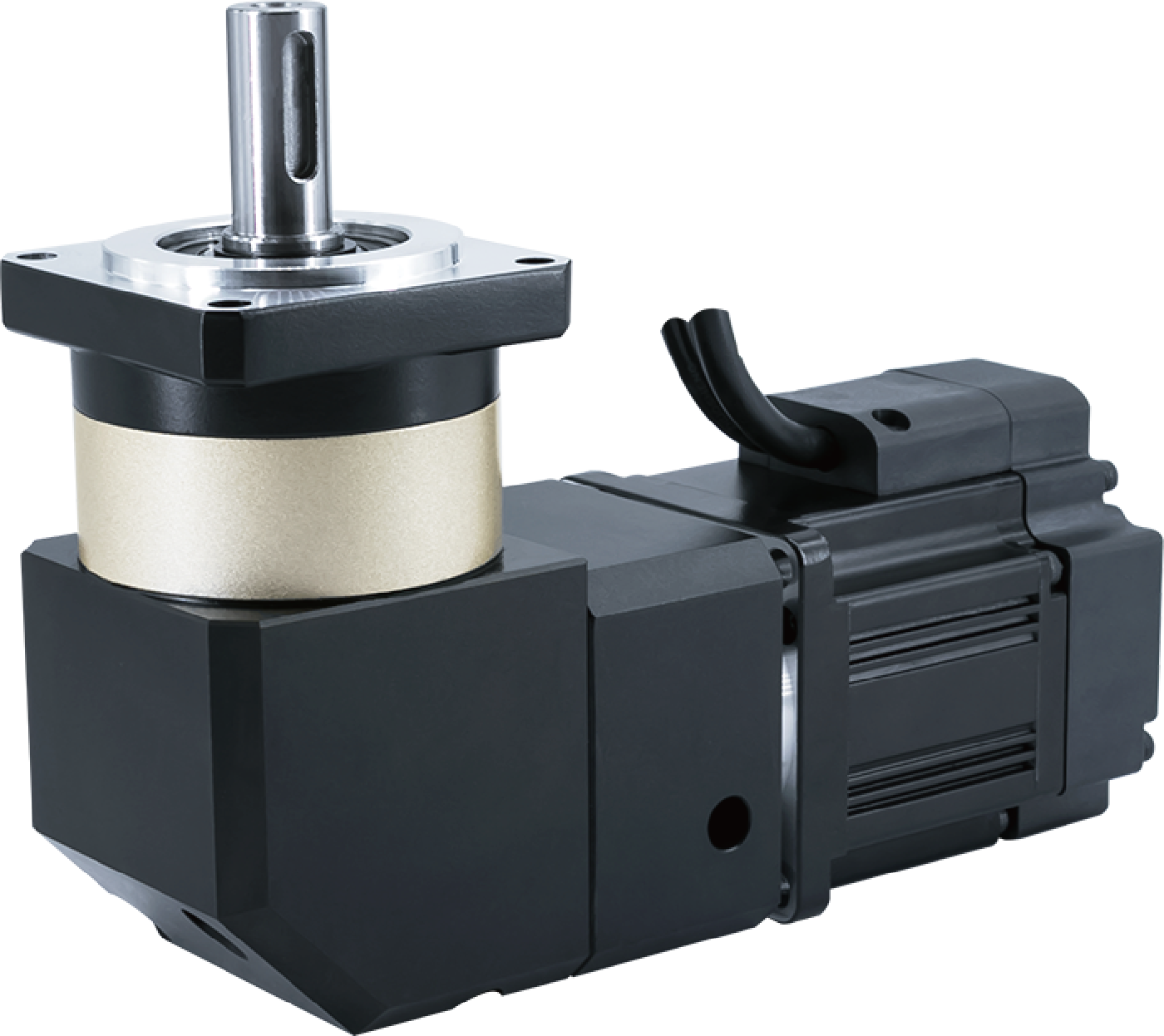

HDBMOTOR offers a complete range of motion control products, including linear lead screw stepper motors, rotary platforms, stepper motors, servo motors, and motor drivers. With rich industry experience and reliable manufacturing capability, we support customers worldwide with professional motor solutions.

Not sure which motor fits your application? Contact HDBMOTOR engineers for professional selection support.

Recommended Articles:

Understanding the servo motor working principle: 5 best tips

How to Control a Stepper Motor with Arduino (NEMA 17 Guide)