How to Control a Stepper Motor with an Arduino: A Step-by-Step Tutorial

Stepper motors are widely used in motion control systems that require precise positioning, repeatable movement, and reliable performance. From CNC machines and 3D printers to robotics and automation equipment, stepper motors remain a popular choice—especially when paired with Arduino.

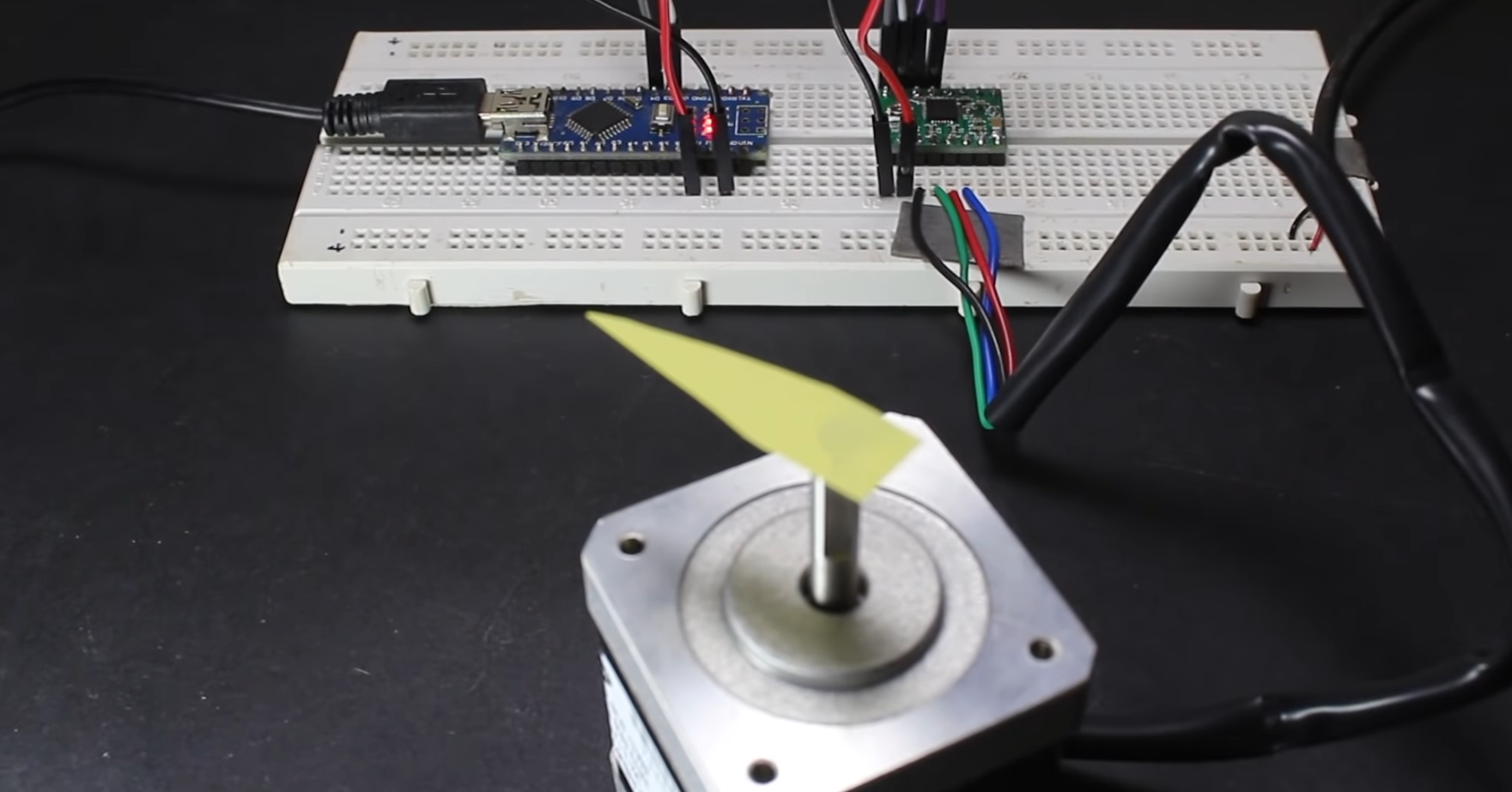

In this step-by-step tutorial, we will show you how to control a stepper motor with an Arduino, using an open-loop NEMA 17 (42mm) two-phase hybrid stepper motor as a practical example. This setup represents one of the most common and proven solutions for Arduino-based motion control projects.

1. Why Use a Stepper Motor with Arduino?

Arduino is widely adopted for prototyping and control tasks due to its simplicity, flexibility, and large ecosystem. Stepper motors are a natural match because they offer:

Precise position control without feedback

Simple pulse-and-direction control logic

Stable low-speed performance

Cost-effective implementation

Unlike DC motors, stepper motors rotate in discrete steps, allowing accurate angular positioning without encoders in most applications.

2. Choosing the Right Stepper Motor for Arduino Projects

For most Arduino applications, the NEMA 17 open-loop stepper motor is the preferred choice.

Why NEMA 17?

Standard 42 × 42 mm frame size

Widely available drivers and accessories

Balanced torque, size, and cost

Easy integration into mechanical designs

Open-Loop vs Closed-Loop

While closed-loop stepper motors offer position feedback, they also introduce higher cost and system complexity. For Arduino-based systems, open-loop stepper motors are sufficient in most cases, especially for prototyping, small automation systems, and educational projects.

In this tutorial, we use an industrial-grade NEMA 17 open-loop stepper motor (Model: SM1702).

3. Stepper Motor Specifications Used in This Tutorial

The following specifications represent a typical NEMA 17 two-phase hybrid stepper motor suitable for Arduino control:

| Parameter | Value |

|---|---|

| Motor Size | NEMA 17 (42 mm) |

| Motor Type | Two-phase hybrid, open-loop |

| Step Angle | 1.8° |

| Rated Current | 1.4 A / phase |

| Phase Resistance | 2.1 Ω ±10% |

| Phase Inductance | 3.4 mH ±20% |

| Holding Torque | 0.30 N·m |

| Duty Cycle | Continuous |

| Insulation Class | B |

| Operating Temperature | -20°C to +50°C |

| Service Life | > 5,000 hours |

These electrical characteristics make the motor compatible with commonly used Arduino stepper drivers such as A4988 and DRV8825.

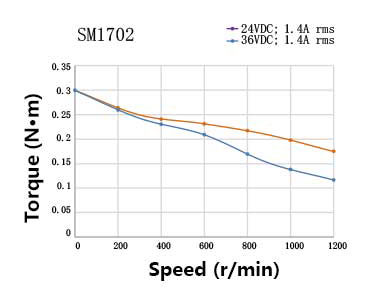

4. Understanding Torque-Speed Performance

Stepper motor performance depends heavily on supply voltage and driver selection.

For the SM1702 motor:

At 0 rpm, the holding torque is approximately 0.30 N·m

At higher speeds, torque decreases due to inductive effects

Increasing supply voltage from 24V to 36V significantly improves torque retention at higher speeds

This behavior highlights an important design principle:

Higher supply voltage helps maintain torque at higher rotational speeds, even when the rated current remains the same.

For applications requiring faster motion or heavier loads, this factor should be considered during system design.

5. Required Hardware Components

To control a stepper motor with Arduino, you will need the following components:

Arduino Uno, Nano, or compatible board

NEMA 17 two-phase open-loop stepper motor (1.8°)

Stepper motor driver (A4988 or DRV8825)

External DC power supply (12V–36V recommended)

Breadboard or PCB

Jumper wires

Optional: heatsink for driver

Note: Do not power the stepper motor directly from the Arduino. Always use an external power supply for the motor.

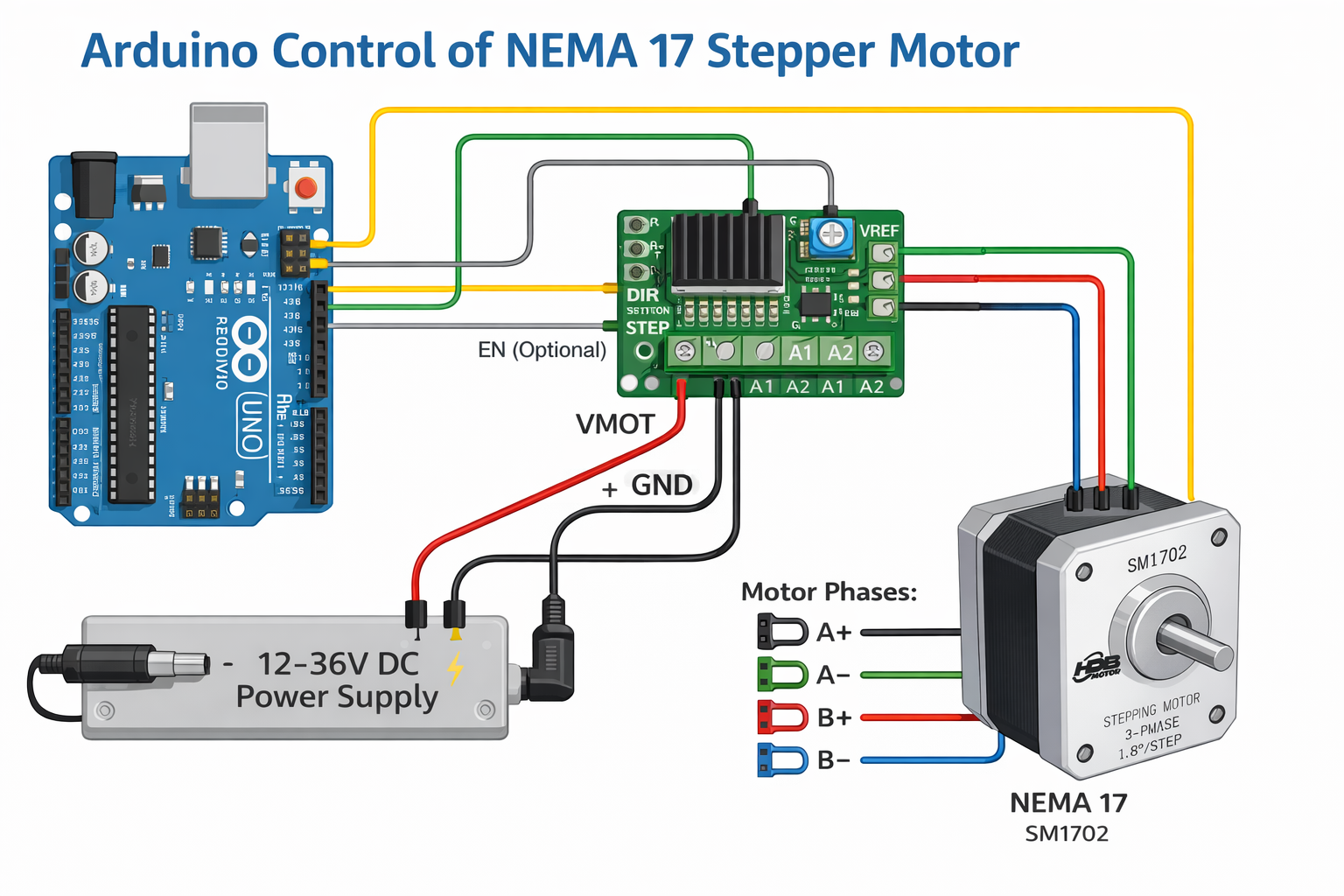

6. Wiring the Stepper Motor to Arduino

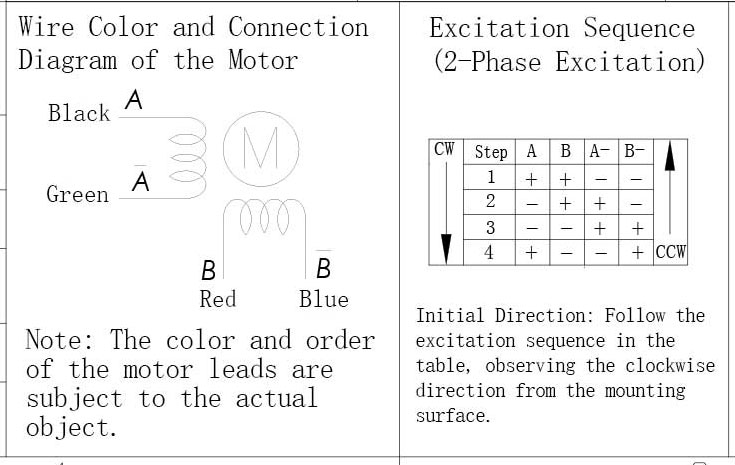

A typical bipolar NEMA 17 stepper motor has 4 wires, corresponding to two motor phases (A and B).

Basic Wiring Overview (A4988 Example)

Motor Phase A → A1 / A2 on driver

Motor Phase B → B1 / B2 on driver

STEP pin → Arduino digital pin

DIR pin → Arduino digital pin

ENABLE (optional) → Arduino or GND

VMOT → External power supply (+)

GND → Common ground (Arduino + power supply)

Correct phase wiring is critical. If the motor vibrates but does not rotate, swap one coil pair.

7. Arduino Code Example

Below is a simple example using the built-in Stepper library. For smoother acceleration and higher performance, libraries such as AccelStepper are recommended.

#include <Stepper.h>

const int stepsPerRevolution = 200; // 1.8° per step

Stepper myStepper(stepsPerRevolution, 8, 9, 10, 11);

void setup() {

myStepper.setSpeed(300); // RPM

}

void loop() {

myStepper.step(stepsPerRevolution);

delay(1000);

myStepper.step(-stepsPerRevolution);

delay(1000);

}This code rotates the motor one full revolution clockwise and then counterclockwise.

8. Current Limiting and Driver Adjustment

Setting the correct current limit on the driver is essential.

For the SM1702 motor:

Rated current: 1.4 A per phase

Adjust the driver’s reference voltage (Vref) according to the driver datasheet to avoid overheating while maintaining sufficient torque.

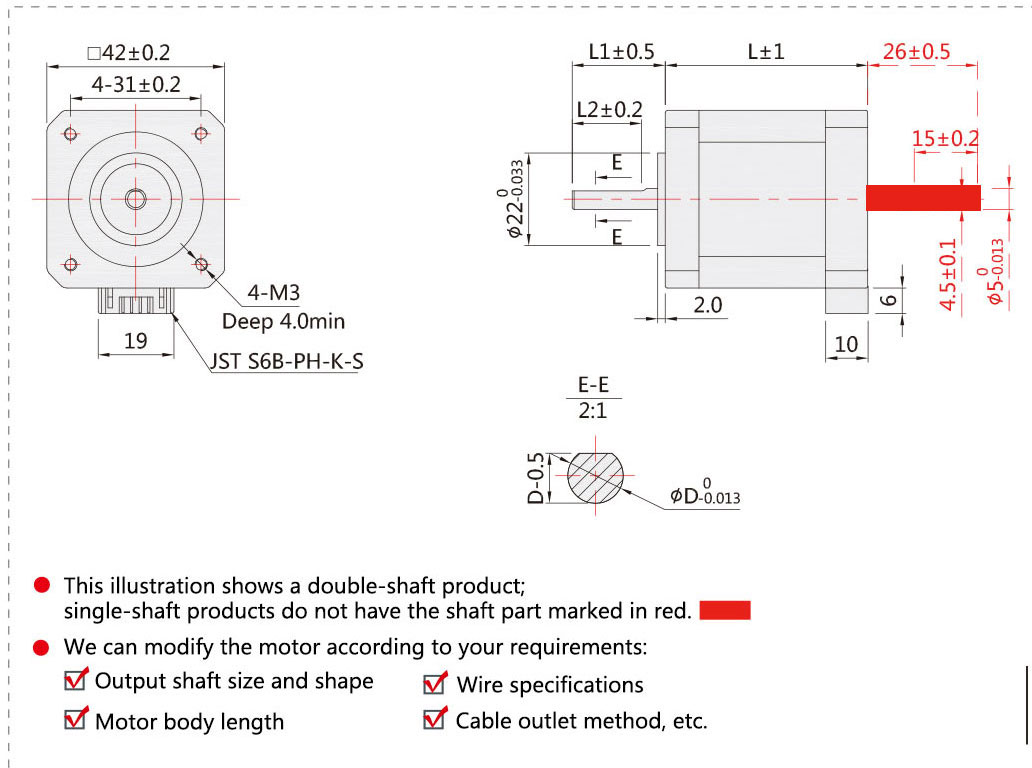

9. Mechanical Integration

The motor follows standard NEMA 17 mounting dimensions, making it compatible with a wide range of brackets, couplings, and linear modules.

Typical applications include:

Linear actuators

CNC axes

Robotic joints

Conveyor positioning systems

Standard shaft dimensions allow easy coupling to lead screws, belts, or gearboxes.

10. Scaling Up: When to Use a Larger Motor

While NEMA 17 motors are ideal for light to medium loads, higher torque applications may require:

NEMA 23 stepper motors

Higher supply voltage

External drivers

Closed-loop systems

For CNC machines, packaging equipment, and industrial automation, upgrading the motor size or control architecture may be necessary.

11. Common Applications

Arduino-controlled NEMA 17 stepper motors are widely used in:

Desktop CNC machines

3D printers

Robotics platforms

Camera sliders

Medical and laboratory devices

Small automation equipment

Their reliability, precision, and ease of control make them a standard choice in motion systems.

12. Final Thoughts

Controlling a stepper motor with Arduino is straightforward when the right components are selected. An open-loop NEMA 17 two-phase hybrid stepper motor, such as the SM1702, offers an excellent balance of performance, simplicity, and cost.

By understanding motor specifications, torque-speed behavior, and proper driver configuration, you can build stable and reliable motion control systems suitable for both prototyping and real-world applications.

If you require detailed datasheets, drawings, or OEM customization options, selecting an industrial-grade stepper motor with consistent electrical and mechanical performance is critical for long-term success.