Three-Phase Stepper Motor Principle and Performance Advantages

Three-phase stepper motors are widely used in industrial automation, semiconductor equipment, medical devices, and precision positioning systems. Compared with conventional two-phase stepper motors, three-phase designs offer higher resolution, smoother motion, and lower vibration, making them an ideal choice for demanding motion control applications.

At HDBMOTOR, we design and manufacture high-performance three-phase stepper motors that combine optimized electromagnetic structure with reliable industrial-grade quality, helping customers achieve stable and precise motion control.

Basic Structure of a Three-Phase Stepper Motor

Early three-phase stepper motors were mainly variable reluctance (VR) types, using rotors without permanent magnets. With the development of hybrid technology, modern three-phase stepper motors now commonly use permanent magnet rotors combined with toothed stator poles.

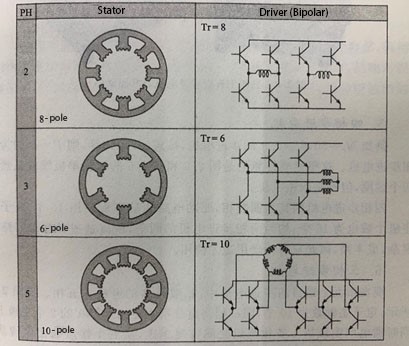

By precisely matching the tooth pitch of the stator and rotor, the motor can achieve finer step angles and higher torque density. In a three-phase stepper motor, the number of stator main poles is always a multiple of three, such as 3, 6, 9, or 12 poles, which ensures balanced electromagnetic forces during operation and reduces vibration.

Three-Phase vs Two-Phase Stepper Motors

When comparing stepper motors with different phase numbers, both performance and system cost must be considered:

Higher Resolution: At the same rotor tooth count, a three-phase stepper motor provides approximately 1.5 times higher resolution than a two-phase motor.

Lower Vibration: Torque ripple is reduced due to smoother electromagnetic force distribution.

Simpler Drive Integration: Three-phase stepper drivers typically require fewer switching power devices than even-phase designs.

These advantages make three-phase stepper motors increasingly popular in applications where smooth motion and positioning accuracy are critical.

Winding Configurations: Y and Delta (△)

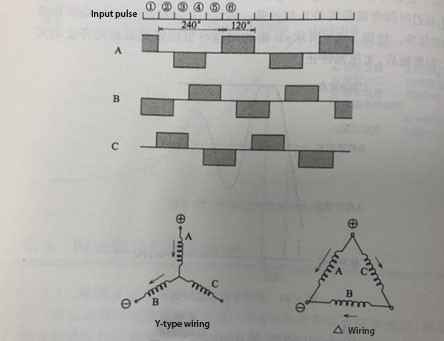

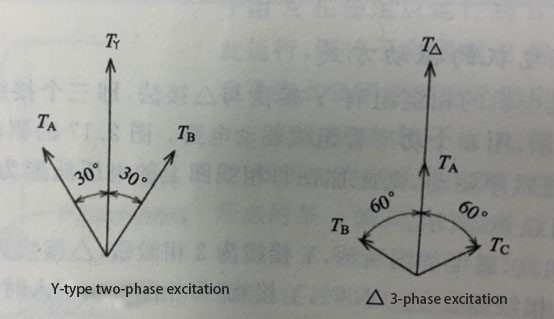

Three-phase stepper motors generally use either Y (star) or delta (△) winding connections, each suitable for different operating conditions.

Y (Star) Connection

Two-phase excitation

Lower phase current

Higher inductance due to series windings

Well suited for low-speed, high-torque operation

Delta (△) Connection

Three-phase excitation

Higher phase current (√3 times that of Y connection)

Lower effective inductance

Better torque retention at higher speeds

At low speed, both Y and delta connections can generate the same torque. However, as speed increases, the delta connection maintains better current response and torque output, making it more suitable for high-speed motion.

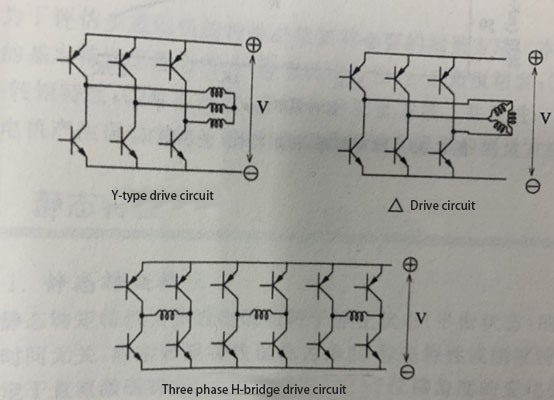

Independent Three-Phase (H-Bridge) Drive

In some high-performance applications, three-phase stepper motors are driven using independent windings with H-bridge circuits. Each phase receives the full supply voltage, enabling the highest rotational speed.

Although this method delivers excellent high-speed performance, it requires more power transistors and increases system cost. Therefore, Y and delta wiring methods remain the most commonly used solutions in industrial environments.

Performance Example

Taking a 42 mm frame, 33 mm body length, 3.75° step angle hybrid stepper motor as an example:

Y and delta connections provide similar torque at low speed

Delta connection performs better at higher speeds

Y connection experiences greater torque drop due to increased inductive reactance

Why Choose HDBMOTOR Three-Phase Stepper Motors

HDBMOTOR focuses on delivering reliable and customizable stepper motor solutions for industrial customers worldwide.

Over 18 years of experience in stepper motor manufacturing

Stable supply for OEM and ODM projects

Consistent torque, low vibration, and long service life

Professional technical support for motor and driver selection

Whether you need a standard three-phase stepper motor or a customized solution optimized for your application, HDBMOTOR can support your project from design to mass production.

Get Technical Support or Pricing

If you are evaluating three-phase stepper motors for your system, our engineers are ready to help.

Contact HDBMOTORto receive datasheets, technical recommendations, or a competitive quotation tailored to your application.

Recommended Articles:

How to Control Stepper Motor Speed

Stepper Motor Continuous Jitter When Returning to Origin