Hollow Shaft Stepper Motor Recommendations and Applications

The hollow shaft stepper motor offers unique advantages due to its hollow rotating shaft, allowing integration with optical components such as lenses and prisms for high-precision rotating optical devices. Additionally, it can connect directly to gearboxes and other mechanisms, saving design space, reducing design time, and facilitating maintenance.

What is a Hollow Shaft Stepper Motor?

A hollow shaft stepper motor features a rotating shaft with a hollow bore. This design enables direct mounting of optical elements or mechanical components inside the shaft, eliminating the need for extra couplings. HDBMOTOR has advanced this technology through unique magnetic circuit design, precise machining, and assembly techniques, enabling high torque and smooth operation even with large hollow shaft bores.

Recommended Models and Specifications

Below are several recommended hollow shaft stepper motor models with their key specifications for your consideration:

| NEMA | Model | Holding Torque (N·m) | Rated Current (A) | Rotor Inertia (g·cm²) | Motor Length (mm) | Shaft Inner Diameter (mm) |

|---|---|---|---|---|---|---|

| 23 | SMK2302 | 1.1 | 4.2 | 280 | ≤56.0 | 12 |

| 23 | SMK2304 | 1.8 | 4.2 | 440 | ≤76.0 | 12 |

| 17 | SMK1702 | 0.32 | 1.4 | 33 | ≤35.0 | 8 |

| 17 | SMK1704 | 0.53 | 2 | 77 | ≤49.0 | 8 |

| 11 | SMK1101 | 0.08 | 1 | 9 | ≤32.0 | 6 |

| 11 | SMK1102 | 0.12 | 1 | 12 | ≤45.0 | 6 |

| 8 | SMK0801 | 0.018 | 0.6 | 1.6 | ≤28.0 | 3 |

| 8 | SMK0803 | 0.036 | 0.8 | 2.9 | ≤40.0 | 3 |

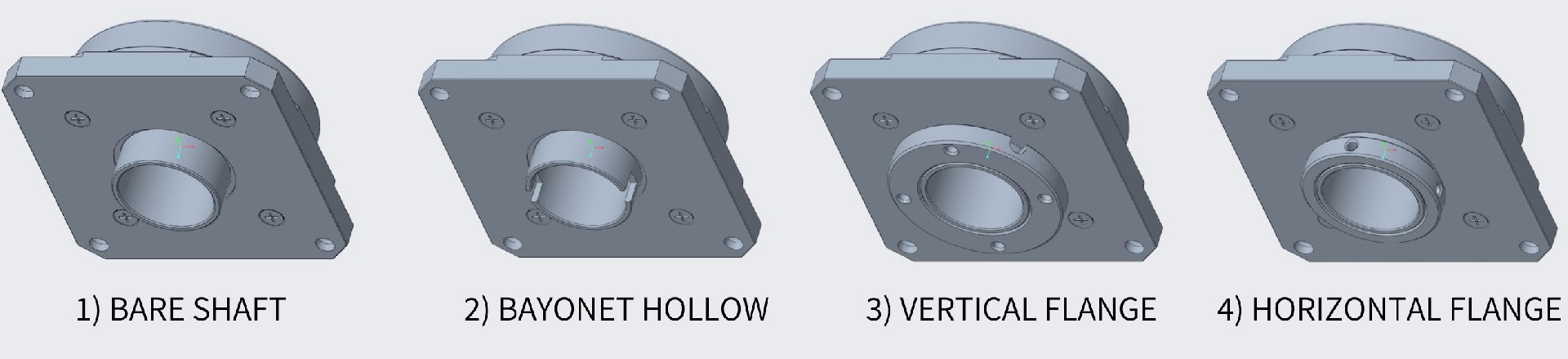

Output Shaft Types

The hollow nature of the shaft leads to different connection types compared to traditional motors. The main mechanical interfaces include:

Bare shaft: simple hollow shaft for direct use.

Bayonet hollow: direct hollow bayonet connection.

Vertical flange: axial threaded hole for mounting.

Horizontal flange: radial threaded hole for mounting.

Applications of Hollow Shaft Stepper Motors

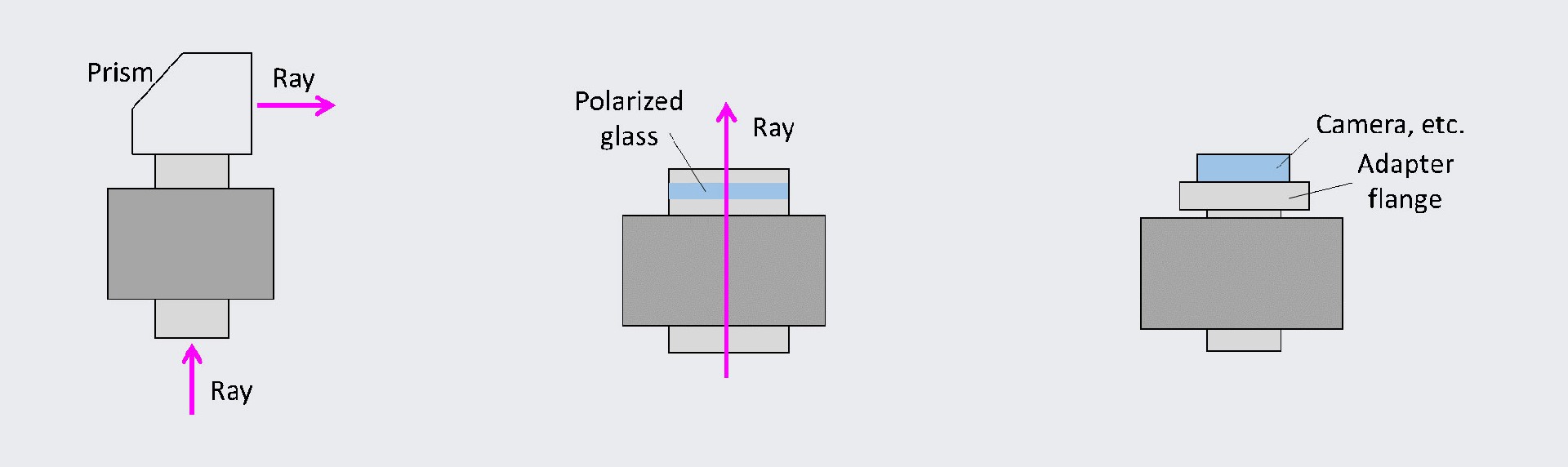

Hollow shaft stepper motors are widely used in semiconductor equipment, optical devices, and motion platforms. Their hollow shaft allows mounting of optical elements such as prisms, polarizers, or cameras inside or outside the shaft, eliminating complex installation and calibration.

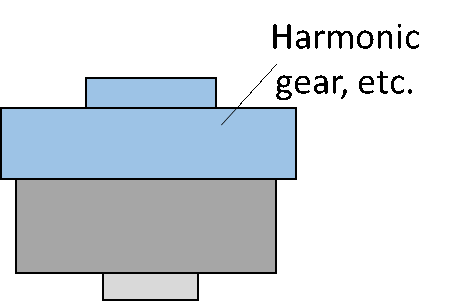

They also integrate well with harmonic gearboxes, providing high torque and precision in compact assemblies, suitable for demanding industrial applications.

Conclusion

The hollow shaft stepper motor combines compactness, multifunctionality, and precision, making it ideal for advanced semiconductor, optical, and motion control applications. HDBMOTOR’ innovative design overcomes traditional limitations, providing motors with high torque and smooth operation even with large hollow shaft bores.

Contact HDBMOTOR’ specialists for customized solutions tailored to your application needs.

Recommended Articles:

How To Control Stepper Motor Speed: 2 Effective Methods Explained

NEMA 17 vs NEMA 23 vs NEMA 34 Stepper Motors: 7 Key Differences & Applications