NEMA Standards and NEMA Motor Classification: A Complete Industrial Guide by HDBMOTOR

In the global electric motor industry, standardization plays a decisive role in ensuring equipment reliability, performance consistency, and long-term interchangeability. As a professional manufacturer of motion control products, HDBMOTOR strictly adheres to international standards to deliver motors that meet industrial-grade quality and global compatibility.

Among all international standards, the NEMA standard—developed by the National Electrical Manufacturers Association—is one of the most widely recognized motor specifications in North America and around the world. Motors designed according to NEMA standards provide predictable dimensions, performance levels, and enclosure classifications, greatly simplifying equipment design and replacement.

This article provides a comprehensive overview of NEMA standards and NEMA motor classifications, along with how HDBMOTOR integrates these standards into its product development.

What Are NEMA Standards?

NEMA standards define the physical and performance parameters of electric motors, including frame sizes, mounting configurations, shaft dimensions, efficiency levels, and environmental protection ratings. Their core purpose is to ensure uniformity, safety, and ease of integration across different manufacturers.

1. Frame and Mounting Dimensions

NEMA frame sizes determine the motor’s physical footprint and mounting interface. They define:

Frame geometry

Mounting hole positions

Shaft diameter and length

Installation height

Common NEMA frame sizes include:

56 Frame — small industrial and commercial applications

143T / 145T — pumps, compressors, conveyors

182T / 184T — medium-power industrial machinery

215T and above — heavy-duty industrial applications

These standardized dimensions allow motors from different manufacturers to be interchangeable without mechanical modifications. HDBMOTOR provides a wide selection of NEMA-compliant frame sizes to support diverse industrial applications.

2. NEMA Efficiency and Performance Standards

Energy efficiency plays a crucial role in modern industrial cost management. NEMA defines two major efficiency levels:

NEMA Premium Efficiency

High-efficiency motors designed to reduce energy consumption over long-term operation.NEMA Energy-Efficient Motors

Motors offering better efficiency than standard models but below premium-level performance.

HDBMOTOR designs motors that comply with or exceed NEMA energy performance requirements, helping users reduce power losses and improve system stability.

3. Environmental Protection Levels

NEMA enclosures determine how well a motor is protected against dust, liquids, and environmental exposure. Common types include:

ODP (Open Drip-Proof): suitable for clean indoor environments

TEFC (Totally Enclosed Fan-Cooled): resistant to dust, debris, and outdoor conditions

TENV (Totally Enclosed Non-Ventilated): geared for specific precision applications

HDBMOTOR offers multiple enclosure configurations to support general-purpose and harsh-environment industrial uses.

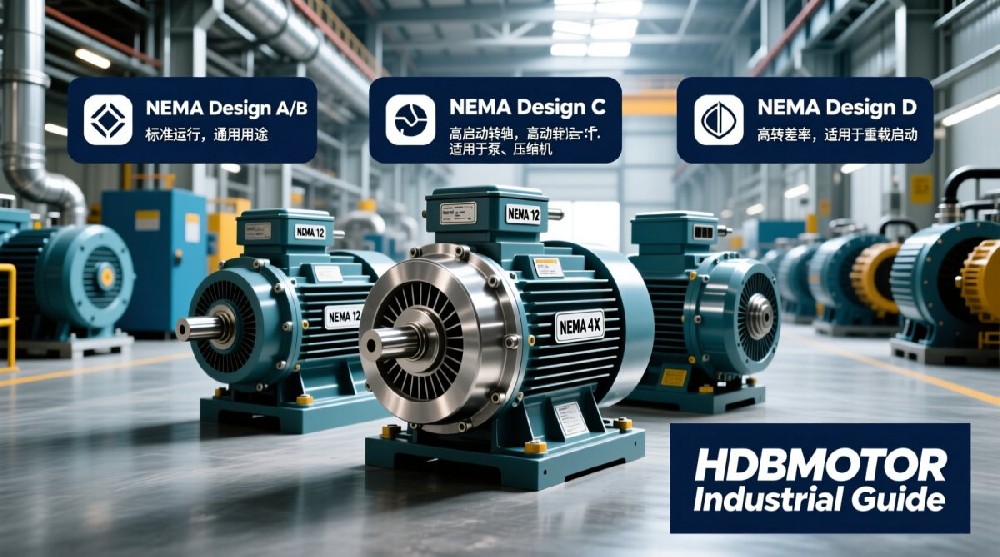

NEMA Motor Classification Types

NEMA classifies induction motors into several categories based on torque characteristics, slip levels, and performance behaviors.

NEMA Class A

Maximum slip ≤ 5%

Medium to high starting current

Suitable for fans, pumps, and general industrial loads

NEMA Class B

Lower starting current than Class A

Standard choice for HVAC systems and general automation equipment

NEMA Class C

High starting torque

Ideal for conveyors and heavy inertia loads

NEMA Class D

Slip between 5% and 13%

Very high locked-rotor torque

Used in cranes, hoists, and high-inertia industrial machinery

HDBMOTOR manufactures motor solutions across multiple NEMA performance classes to support applications ranging from light-duty motion control to heavy industrial lifting.

NEMA Frame Sizes Used in Modern Motion Systems

NEMA standards are widely applied in stepper motors, servo motors, and industrial drive systems. HDBMOTOR offers a broad range of NEMA-compliant frame sizes, including:

NEMA 6, 8 — micro-precision equipment

NEMA 11, 14, 16, 17 — 3D printers, medical devices, compact automation

NEMA 23, 24 — CNC equipment, robotics, automated machinery

NEMA 34, 42 — logistics, packaging, heavy-duty automation

These standardized frame sizes ensure seamless integration with global mechanical designs while maintaining consistent performance and reliability.

Conclusion

NEMA standards provide essential guidelines that unify the design, safety, efficiency, and compatibility of electric motors worldwide. For engineers, system integrators, and equipment manufacturers, selecting motors that comply with NEMA standards ensures long-term scalability and ease of maintenance.

As a trusted industry manufacturer, HDBMOTOR develops motors that fully conform to NEMA specifications—delivering robust performance, precise dimensions, and dependable operation across a wide range of industrial applications. With complete product coverage from micro-motion motors to high-power industrial drives, HDBMOTOR ensures stable and efficient motor solutions for modern automation needs.