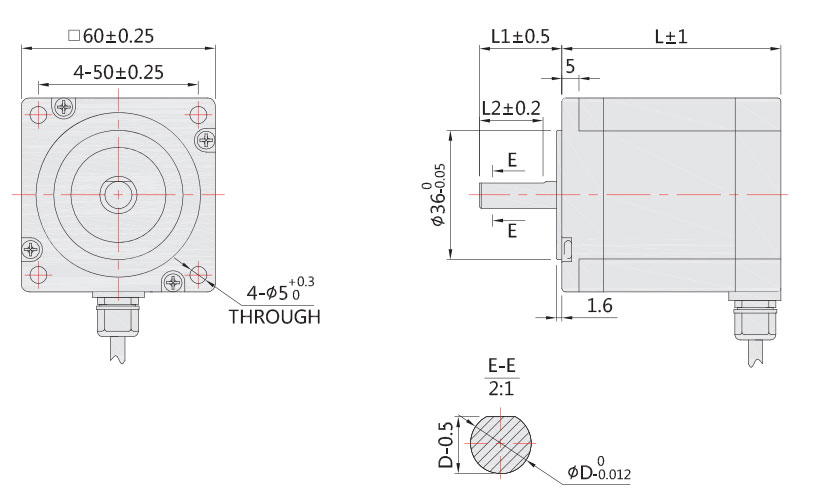

1、Shaft Options: Various shaft types are available, including single flat, double flat, keyway, and gear teeth.

2、Lead Wire Options: Customized winding and lead wire configurations can be provided according to different application requirements.

3、Accessory Options: A variety of stepper motor accessories are available, such as planetary gear reducers and encoders.

4、Usage Notes: Pay attention to tolerance fits during use. When connecting the motor to the driver, do not miswire the phases.

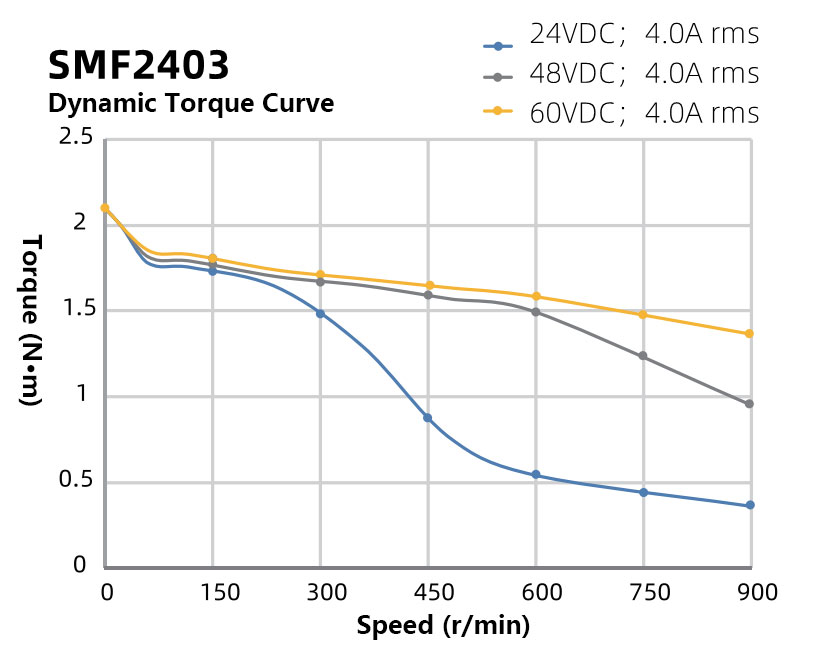

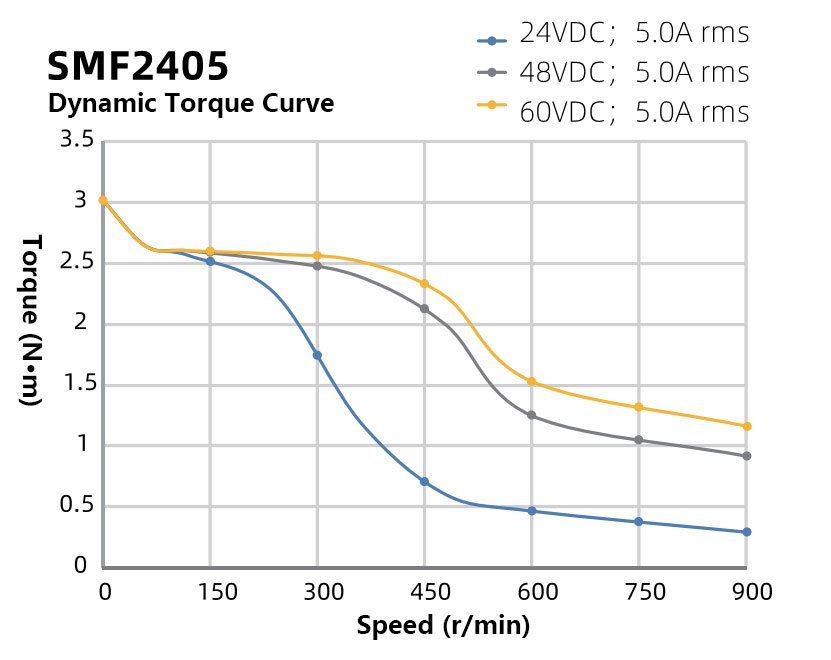

Stepper motors are not constant torque motors; the higher the operating speed, the smaller the output torque. Therefore, while paying attention to the motor holding torque parameters, more attention should be paid to the motor’s output torque at actual operating speeds (refer to the dynamic torque curve). We also recommend reserving a 1.5 times margin to avoid step loss due to overload.

| Model | Holding Torque (N.m) | Rated Current (A) | Rotor Inertia (g.cm²) | Motor Length (mm) | Waterproof Rating | Recommended Driver |

|---|---|---|---|---|---|---|

| SMF2403 | 2.1 | 4.0 | 490 | ≤70.0 | IP65 | Low speed S-245D 24-48VDC High speed S-266D 24-60VDC |

| SMF2405 | 3.0 | 5.0 | 1200 | ≤100.0 | IP65 |

The "Recommended Driver" listed above is a pulse-type stepper motor driver. Additionally, we can provide customers with:

Bus-type stepper drivers (RS485, CANopen, EtherCAT communication control); intelligent stepper drivers (potentiometer speed control, built-in PLC programming functions, etc.).